Overview

Europe’s rail vehicles require a step change in technologies and design to remain competitive. Innovative materials and modular design for rolling stock are considered to become a key to success. Composite materials have demonstrated a high potential for lighter, more energy- and cost-efficient structural components. However, currently available structural composites do not meet Fire, Smoke & Toxicity (FST) requirements of the railway sector, and cannot be used for the manufacturing of carbody shell parts.

The overall aim of the Mat4Rail project was to lay the foundation for reducing train weight by replacing metal parts with Fibre Reinforced Polymers (FRPs) and increasing capacity and passenger comfort via built-in modularity of train interior design.

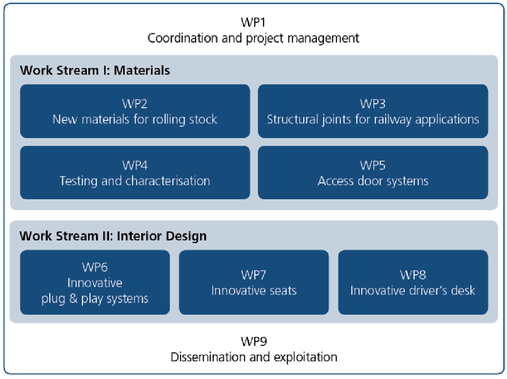

The Mat4Rail project was divided into nine work packages (WPs) and two work streams

Work Stream I: Materials

Materials aimed to develop FRPs that met all the railway environment requirements regarding Fire, Smoke, and Toxicity, mechanical performance, and cost-effective manufacturing, to develop structural joints for FRPs, and to innovate the access door system.

Work Stream II: Interior Design

Interior Design addressed the challenges and shortcomings of current rolling stock in terms of modularity in use, to meet the changing passenger demand during the 30-40 years of an in-service operating life-cycle of a train.